- Cobbles & Pebbles[1]

- Artificial Stone[1]

- Tiles[1]

- Crystal[1]

- Garden Ornaments[1]

- Stone Crafts[1]

- Mosaics[1]

- Plastic Masterbatches[1]

- Mobile Phone Housings[1]

- Golf Balls[1]

- Plastic Sheets[1]

- Other Toys & Hobbies[1]

- Other Gifts & Crafts[1]

- Energy Saving & Fluorescent[1]

- Pigment[7]

- Packaging Rope[1]

- Slippers[3]

- Polyester Fiber[1]

- 100% Polyester Yarn[1]

- Thread[1]

- Lamp Covers & Shades[1]

- Packaging Label[1]

- Safety Helmet[1]

- Other Security & Protection Products[1]

- Other Plastic Building Materials[1]

- Other Safety Products[1]

- Adhesive Tape[1]

- Contact Person : Mr. Zhang Clive

- Company Name : Dalian Lightleader Technology Co., Ltd.

- Tel : 86-411-84516155

- Fax : 86-411-84365151

- Address : Liaoning,Dalian,B2201,19 Shida Street,High Tech zone

- Country/Region : China

- Zip : 116025

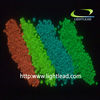

Photoluminescent Plastic Masterbatch

LIGHTLEAD Photoluminescent Plastic Pellets are particularly for certain resins such as PP, PE, PMMA, PC, etc. By injection, extrusion and blowing molding, you can use photoluminescent plastic pellets directly to make luminous plastic products.

These products can glow continuously in the dark more than 10 hours after absorbing various visible lights for 10-30 minutes, and without any toxicant and radioactivity.

Our standard percentage of the photoluminescent pigment in the photoluminescent plastic pellets is 25% and 50%. The brightness and afterglow time of your finished products could be adjusted by yourself by adding more resins into the compounds. In order to make your photoluminescent finished products get various colors, you can choose photoluminescent pigment in different colors. Otherwise, you can also use dyes/pigment to colorize it. But the dyes/pigment can definitely affect the brightness and afterglow time of the finished products. One with higher brightness and use light color dyes/pigment to minimize the loss of t he brightness.

Many customers like to use photoluminescent pigment directly. Some of them found that there is blacken phenomenon. If you have fewer knowledge of photoluminescent pigment, this blacken phenomenon is hard to solve. Finally, the appearance of the finished plastic products looks not very good. The photoluminescent plastic pellets and masterbatch could help you overcome this difficulty.

The photoluminescent pigment is in powder form but the photoluminescent plastic pellets and masterbatch are in granule form.

The equipment is new designed. The hardened screw and barrel are used to prevent the PL masterbatch from blackening. The programming control measuring pump is assembled to the equipment to guarantee the pigment loading volume. The importance is that the way of weeding is changed to decrease the shear and friction strength.

The universal plastic resin is used to ensure the easy application of Lightlead masterbatch and the high performance photoluminescent pigment is used to achieve good photoluminescent effectiveness.

The chemical and physical characteristics can be improved by adding some addititives beforehand.

Photoluminescent Plastic Masterbatch